Masterbatches with laser additive

Laser marking technology enables durable and sustainable marking for a wide range of plastics. Products can be uniquely personalized using lasers, the markings can withstand extreme conditions and can contribute to counterfeit protection.

The masterbatches are individually equipped with laser additive and tested for the optimum marking solution using NIR technology. Both pure laser batches and combination batches with the desired color are possible for opaque and transparent plastics.

Fibaplast laser marking – permanent precision

Manufacturers of plastic products are increasingly turning to laser marking technology for a number of reasons. It is an attractive option for companies that value precision, diversity and environmental friendliness. Products can be marked without the use of labels or sleeves, which increases recyclability and reduces the carbon footprint. In addition, lasered serial numbers, logos or other identification features are permanently legible and are not affected by external influences.

With the Fibaplast laser marking product range, we offer a customized masterbatch solution. Depending on the type of plastic and additive, this can either be carbonized (for dark marking) or foamed (for light marking).

Our new masterbatches for colored markings are highly visually appealing. Depending on the desired color, they create high-contrast, individual designs on a dark background.

Fibatec laser series – Innovation in marking technology

Transparent laser marking enables individual and interesting marking of transparent plastics such as PC, PET or PMMA. The new laser additives in the Fibatec series create a special effect: the marking appears as if it has been lasered inside the matrix. In addition, the surface remains demonstrably free of damage and the properties of the plastic are not impaired.

Our translucent marking laser additives also create impressive designs. By using different marking parameters, various effects and degrees of transparency can be created on the plastic surface.

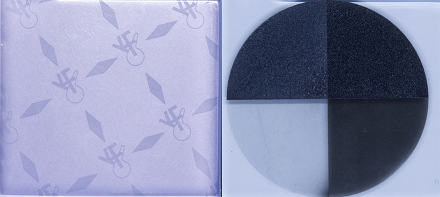

Light and dark marking

A light marking on a dark background is caused by foaming. The dark marking on a light background is caused by carbonization.

Colored marking

Colorful marking is possible on a dark background.

Transparent marking

Depending on the type of laser additive, a depth effect or a marking that is not damaging to the surface can be created.

The color selection of masterbatches with laser additives

We develop the desired color shade individually for you and determine the optimum laser additive for your preferred design and application. Whether opaque or transparent colors, whether light, dark, colorful or transparent marking – the result will inspire you.

The application areas of masterbatches with laser additive

Our masterbatches for laser marking can be used for the production of almost all thermoplastics, especially for injection molding and extrusion applications. Wherever permanent markings are of great importance and complex component geometries make conventional marking processes impossible, masterbatches with laser additive are of great benefit.

Color setting

In joint coordination with our customers, we define the project requirements for the color setting.

Product request

You need information, have questions or want a quote for the production of a color? Then please feel free to send us your inquiry.

Contact now

How colorful can it be?

Do you have questions about customized colorants and additives for the entire polymer spectrum?

We have the right answers for you.